Dear Sir/Madam,

Hope you have a nice day!

Today I would like to share the information about how to secure the container using twistlocks during transportation.

How to Secure the Container Using Twistlocks in Transportation?

When the container is loaded onto the trailer, it needs to be secured in proper place, so that it doesn’t dislodge and guarantee the container safety during transport.

Corner castings are located on each corner of the container – four at the bottom corners and the other four at the top corners. These corner castings allow shipping containers to be easily secured in place using twistlocks.

Each trailer has four twistlocks, one on each corner. You’ll notice that when loading a container on a trailer, the corner castings are resting on the twist locks on each end of the trailer.

Next, rotate the twist lock handle 90 degrees to lock it in place. This will ensure that the container stays locked down at each corner and is securely connected to the trailer, as it’s crucial for ensuring a safe transport.

In addition, the shipping container needs to be checked on the undercarriage, doors, walls, ceiling and twistlocks. During loading, parts of the container may become damaged or dislodged and need to be checked. Prime Mover and Trailer need to be checked on brakes, lights (prime mover / trailer), fire extinguisher and tire pressure (prime mover / trailer). Ensure that nothing is damaged during the loading process. By this way, you can secure thee container safety in transport.

How to Secure the Container Using Twistlocks in Transportation?

This is Anna from Shandong TITAN Vehicle Co., Ltd.. Established in 2004, as a professional semi trailer supplier in China, our company has successfully exported 27,000 semi trailers to 60 countries worldwide.

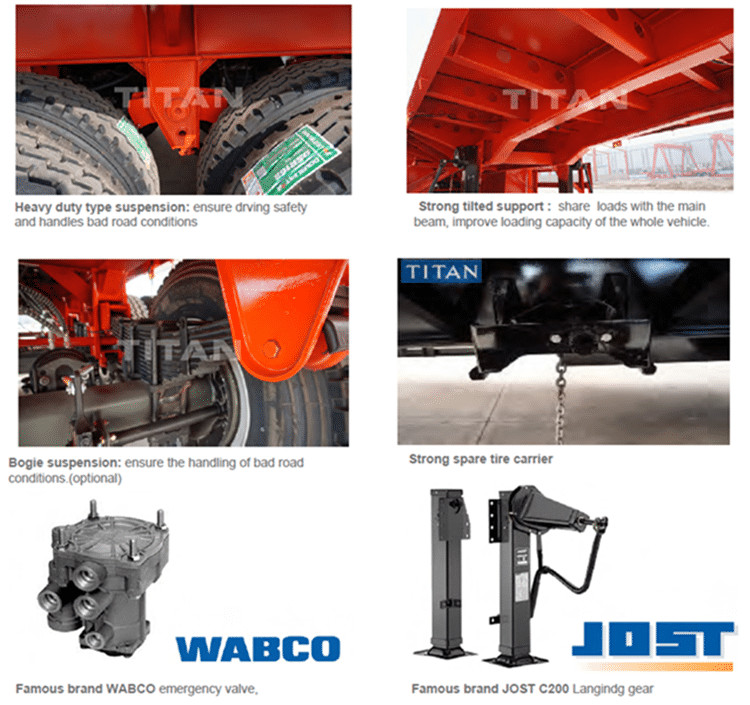

We have made enough preparation for the safe transport of containers. The following are the strengths of TITAN container flatbed trailer.

1.Main beam

We adopt the low carbon high strength alloy steel Q345 to make the main beam, so it has the higher load-carrying capacity and longer service life more than 10 years.

The main beam is integral without welded interface. We use automatic submerged ARC welding technology to weld the main beam. There is no welded joints between the upper, middle and lower plates of the beam, so it can ensure the wholeness of the main beam and make the beam more solid and durable.

2.Polyurethane paint

We adopt the Polyurethane paint for all of our trailers which has high adhesion, more beautiful colors, and the cost is twice of ordinary paint. The strength is the paint will not peel off after more than five years of use.

How to Secure the Container Using Twistlocks in Transportation?

3.We have 6 beams under the floor plate. It effectively ensure the flatness of the floor plate. The floor plate is the 3mm diamond plate, It is thicker than the 2.5mm or 2mm floor plate of other factories. The floor plate is strong and durable, and is not easy to deform.

4.The twist locks do not damage the structure of side beams, which ensures the strength of beam. The crossbeam fixing container adopts the larger and thicker 12# channel steel (120mm).

Other factories break the side beams when installing the container locks. It will greatly reduce the trailer’s loading capacity and lead to deformation under heavy load. In addition, it is easy for the container locks to fall out of the container and finally the container may fall to the ground.

With the support of these strengths, your container or other cargo can be properly secured in transport.

How to Secure the Container Using Twistlocks in Transportation?

By the way, my whatsapp is +86-15854170398. May I know yours? I would share more pictures and videos on it , and we can conveniently talk more details about the trailer.

If have need or interest, please feel free to contact us. We will provide the best transportation solution for you.