Chapter 1: What is Bulk Cement Trailer?

Chapter 1.1: Bulk Tanker Trailer Features

Chapter 1.2: Application of Bulk Cement Trailer

Chapter 1.3: Advantages of Bulk Cement Trailer

Chapter 2: Different Types of Bulk Cement Trailer

Chapter 3: What is the Capacity of Bulk Cement Tanker?

Bulk cement trailer is a special semi-trailer used to transport bulk cement or other bulk construction materials. It has a large-capacity tank and is usually made of high-quality steel. This bulk tanker trailer transports bulk material from loading point to unloading point by compressed air or turbine to meet the demand for bulk cement in construction sites, concrete mixing plants, etc.

Bulk tanker trailer has the following excellent features to ensure the safe transportation of your cargo:

Super Durability: The bulk tanker trailer is manufactured using high-quality steel, which has excellent corrosion resistance and compression resistance, ensuring long-term service life.

High efficiency: The bulk tanker trailer adopts advanced compressed air system or turbine technology to realize fast and reliable bulk cement unloading and improve loading and unloading efficiency.

Customizable options: Depending on your specific needs, we offer a variety of configurations and size options to ensure the best fit for your shipping requirements.

Safety design: The bulk cement tanker is equipped with advanced brake system, anti-tilt mechanism and emergency stop device to ensure safety during transportation.

Low maintenance cost: Our bulk cement tank semi trailer has a simple design and is easy to maintain, reducing repair and maintenance costs.

What is Bulk Cement Trailer?

What is Bulk Cement Trailer?

Construction Sites: The bulk cement trailer transports bulk cement to construction sites for the needs of concrete mixing, masonry and other construction projects.

Building material suppliers: As an important link in the building material supply chain, it provides efficient and reliable cement transportation solutions for building material suppliers.

Logistics companies: bulk cement trailers assist logistics companies in transporting bulk construction materials from production sites to sales sites, ensuring a smooth supply chain.

High Quality and Reliability: The bulk tanker trailer undergoes strict quality control to ensure stable performance and reliability.

Competitive Prices: We offer bulk tanker trailers with competitive prices, helping you reduce shipping costs and increase profits.

Customized solutions: According to your needs, we can provide customized design and configuration options

High-Quality Bulk Cement Trailer | What is the Capacity of Bulk Cement Tanker?

High-Quality Bulk Cement Trailer | What is the Capacity of Bulk Cement Tanker?

Bulk cement trailer is a heavy-duty trailer specially used for transporting bulk cement, it transports cement from one place to another through efficient pneumatic conveying system. Traditional cement transportation methods, such as bagged cement, not only have high transportation costs, but are also easily damaged during handling. The bulk tanker trailer provides a more economical, efficient and environmentally friendly way to transport cement.

The main structure of Bulk cement tanker includes tank body, air compressor, piping system, bracket and bearing etc. Tanks are usually V-shaped, W-shaped or shoe-shaped to improve storage space utilization and transportation efficiency. The air compressor is responsible for injecting compressed air into the tank to transport the cement from the tank to the destination. The piping system is responsible for connecting the air compressor and the tank to ensure airtightness and delivery efficiency. The brackets and bearings provide stable support and driving ability for the trailer.

The working principle of Bulk cement tanker includes processes such as pneumatic conveying, gravity unloading and gas-solid separation. First, the air compressor sends compressed air into the tank, so that the cement flows from the tank to the destination along the pipeline under the action of air pressure. Then, during unloading, gravity will help the cement flow smoothly from the pipe. Finally, the gas-solid separator separates the cement from the air to ensure the quality of the cement.

In the manufacture of bulk cement tank semi trailer, commonly used materials include carbon steel, stainless steel and aluminum alloy. These materials have good strength, wear resistance and corrosion resistance, and can meet different transportation needs. In addition, there are many options for the transportation capacity and size of the bulk cement trailer, such as 25 tons, 30 tons, 40 tons and other different loads, so as to adapt to different scales of engineering projects.

When purchasing a bulk cement trailer, factors such as manufacturer's choice, after-sales service and applicability need to be considered. First of all, it is very important to choose a manufacturer with good reputation and technical strength to ensure the purchase of high-quality products. Secondly, good after-sales service can provide users with timely technical support and guarantee. Finally, choose the appropriate bulk cement trailer type and specification according to the actual transportation needs and engineering characteristics.

Bulk cement trailers are widely used in engineering projects, such as infrastructure construction, industrial and civil buildings, special places, etc. In these fields, bulk cement trailer provides a more efficient, safe and environmentally friendly solution for cement transportation.

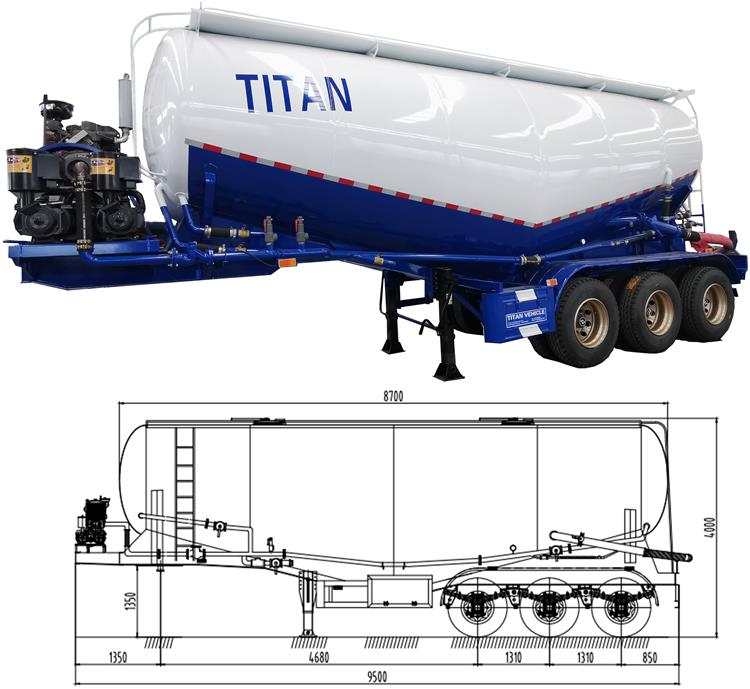

Different Types of Bulk Cement Trailer

Different Types of Bulk Cement Trailer

In order to ensure the normal use and prolong the service life of the bulk tanker trailer, daily inspection, regular maintenance and safe operation are required. Daily inspection includes cleaning and repairing of tanks, pipes, bearings and other components. Regular maintenance includes replacement of damaged parts, lubrication, corrosion protection, etc. Safe operation and protection mainly include measures such as explosion-proof, fire-proof, and anti-skid to ensure the safety of operators and equipment.

Bulk tanker trailer has significant advantages and importance in modern cement transportation. With the continuous development of technology and the improvement of manufacturing process, the performance of bulk tanker trailer will be further optimized. The industry should pay attention to the development and application of bulk cement tank semi trailer to provide better transportation solutions for infrastructure construction.

Bulk cement trailers generally come in two types of tank designs: V-shaped tanks and W-shaped tanks. Their main difference lies in the internal structure and use effect of the tank.

V-shaped tank means that the inside of the tank is V-shaped. This design can make powdery materials flow and distribute better inside the tank during transportation. The V-shaped tank is characterized by high transport efficiency and fast unloading speed, and is suitable for transporting dry powder materials with relatively low density. Due to the relatively large internal space of the bulk tanker trailer and the high center of gravity of the V-shaped tank, it is necessary to pay attention to balance and stability during transportation.

W-shaped tank means that the inside of the tank is W-shaped. This design can make the powdery materials more evenly distributed inside the tank during transportation. The characteristic of the W-shaped tank is that it is suitable for transporting dry powder materials with high density. The internal structure of bulk cement tank semi trailer can effectively reduce the accumulation and agglomeration of powder materials. Due to the relatively small internal space of the bulk cement trailer tank, the W-shaped tank has a lower center of gravity and better balance and stability during transportation.

The V-shaped tank is suitable for transporting dry powder materials with low density and has high transportation efficiency, while the W-shaped tank is suitable for transporting dry powder materials with high density and has better stability and fluidity. Which type of bulk cement trailer to choose should be selected according to specific transportation needs and material characteristics?

Different Types of Bulk Cement Trailer

Different Types of Bulk Cement Trailer

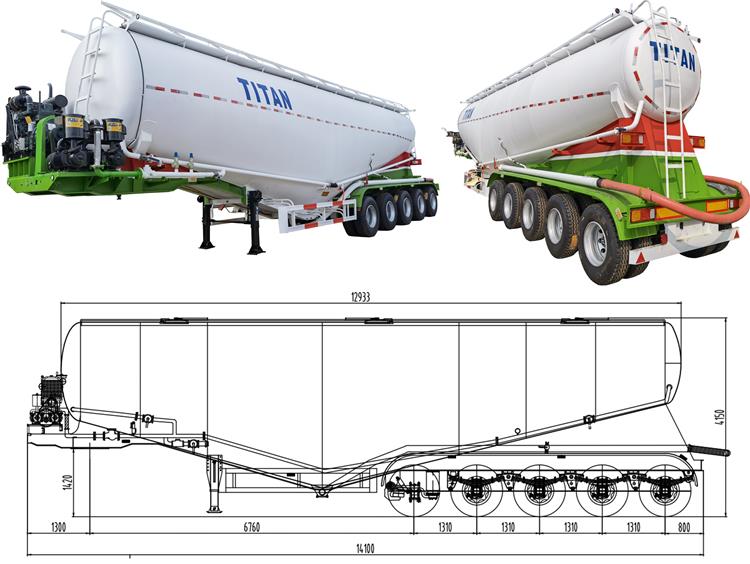

The capacity of a Bulk cement trailer may vary depending on its size and design. Generally, these tankers are used to transport dry bulk materials such as cement, fly ash or other powdery substances. Capacity is usually measured in volume, usually expressed in cubic meters (m³).

Bulk tanker trailers come in different sizes, and it is worth noting that specific regulations and standards may vary in different countries or regions, so the capacity of a bulk cement carrier may also be affected by local regulations and industry practices.

The capacity of a Bulk tanker trailer varies according to its size and design. Generally speaking, the bulk cement tank semi trailer has a capacity of 20 tons to 120 tons. However, larger capacity bulk cement trailers can also be custom designed to meet specific requirements.

The capacity of a Bulk tanker trailer largely depends on its size and number of compartments. Most bulk tanker trailers have a single compartment, but some tankers can have multiple compartments, allowing different types of cement or other dry bulk materials to be transported in one trip. The capacity of each compartment may vary depending on the bulk cement tank semi trailer design.

It is important to note that the maximum capacity of a bulk cement trailer may also be affected by local regulations and road restrictions. Some regions or countries may have weight and size restrictions that limit the capacity of tank trucks that can be used on their roads. Therefore, when choosing a bulk cement trailer, it is important to consider local regulations and restrictions to ensure compliance and safe transportation.

The capacity of a Bulk cement trailer varies by its size and design. Generally speaking, the bulk tanker trailer has a capacity between 20 tons and 120 tons. However, some larger tankers have a capacity of 150 tons or more.

It is worth noting that the capacity of bulk cement tankers is usually calculated by weight rather than volume because cement is usually shipped in bulk by weight. The weight capacity of a bulk cement tank semi trailer is determined by its maximum load capacity, which is influenced by factors such as tank size, wall thickness and the vehicle's own weight.

What is the Capacity of Bulk Cement Tanker?

What is the Capacity of Bulk Cement Tanker?

bulk cement trailer , bulk tanker trailer , bulk cement tanker , bulk cement tank semi trailer.